Mixing by Dispersion

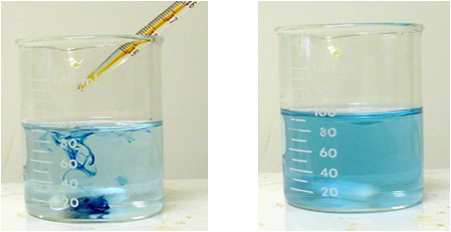

While the traditional methods of “wet chemical analysis” are carried out in a batch mode (“beaker chemistry”) that allows homogenous and instant mixing of sample with reagents, flow injection techniques are based on controlled dispersion of the sample zone, which forms a concentration

gradient while the sample zone moves towards a detector.

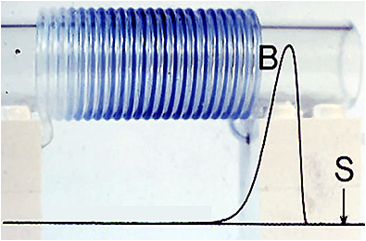

The response of the flow injection system is therefore result of two processes, both kinetic in nature: the physical process of dispersion of sample zone and the chemical process of formation of chemical species. Consequently, the FI system must be constructed in such a way that the radial dispersion is maximized, while the axial dispersion is controlled to suit the assay protocol.

Since it is feasible to achieve instant mixing in radial direction, the limiting factor in achieving fast response, and a high sampling frequency, is the reaction rate. Fortuitously a great majority of regent based assays is based on fast chemical reactions. Occasionally the reaction rate can be enhance by catalysis or by elevating temperature.

J. Ruzicka & E.H.Hansen, “Flow Injection Analysis” 2nd ed. J. Wiley, N.Y. 1988

1.2.3.